“Manufacturing is more than just putting parts together. It’s coming up with ideas, testing principles and perfecting the engineering, as well as final assembly.”—James Dyson, British inventor

Today’s hearing aids are technological marvels that deliver life changing results. While the technology may be complex, making them also requires a human touch. It’s fascinating to see how this marriage of technology and craftsmanship comes together to produce modern hearing aids.

I recently had a chance to look behind the curtain to see how one company does it. Starkey is North America’s only global manufacturer and operates in over 100 countries. With Starkey’s Chief Innovation Officer Dave Fabry as my guide I got an eye opening tour of their headquarters in Eden Prairie, Minnesota.

At Starkey, says Bruce Shamla, it’s about bringing craftsmanship and technology together in one tiny package. A process he oversees as Senior Value Stream Manager.

In many ways, Shamla is a choreographer. Hearing aids may be tiny but they are packed with many parts and, depending on the model being assembled, that includes everything from speakers to ear molds. All of these pieces have to be tracked, delivered to the right spot at the right time and then assembled with precision.

It’s a complex dance.

Adding to the challenge is that these devices are marvels of miniaturization. The Evolv AI CIC (Completely-In-Canal) model for example is virtually invisible.

Its tiny size required Starkey’s engineers to come up with a clever innovation that made it possible.

Bluetooth connectivity is necessary to interact with your smartphone, other devices and your audiologist’s equipment. And if you wear two aids they communicate with each other to distribute sounds between them.

But making it small enough to fit out of sight inside the ear canal presented a problem that was, well, in your head.

Bluetooth radio signals are blocked by the head. That’s not a problem with behind-the-ear devices since the antenna is outside the ear canal. But with CIC aids the antenna is blocked and unable to communicate with its counterpart in the other ear.

The solution? If you look at the picture of the Evolv AI CIC (above) you can see the small wires that are used to remove them from the ear. Those wires do double duty and serve as antennas as well. An innovation that was developed with the help of “Popeye”.

Popeye’s head has the same density and mass as a human head which makes him ideal for testing bluetooth transmissions and antennas.

The heart or more accurately the brain of the hearing aid is a microchip, itself a marvel of miniaturization.

They are essentially little computers and they contain Starkey’s “secret sauce”, the proprietary algorithms developed by Chief Technology Officer Achin Bhowmik and his team.

With an AI assist they analyze the sounds around you to detect speech, and extract it from extraneous noises to deliver a cleaned up signal.

Also tucked away on the circuit board are the accelerometers and gyroscopes that detect if the wearer has taken a fall. If a fall is detected an alert is sent, once again via bluetooth, and your smartphone lets family or friends know.

Other sensors supply information for the suite of features on the Thrive app, including your physical activity and mental engagement.

One of the most important connections between you and your hearing aid is not electronic. Ear molds are usually necessary for those with hearing loss that spans the full range of frequencies.

They’re made from a cast of the ear canal using a soft molding compound to ensure a snug, comfortable fit.

In fact, Starkey got its start some 50 years ago making ear molds. Today they’re made by 3D printers using the cast a template. One day soon there will be no need for the cast.

Instead, a small specialized camera will be used to “map” the ear canal and that information will be sent directly to the 3D printer.

Making sure that all of these myriad parts and the final product perform as they should is Brian Dahl’s job.

He’s the Quality Assurance Manager and, in a way, his office is the world. It’s packed with equipment that can simulate the environment virtually anywhere on earth.

For example, how will the hearing aid perform in the Arctic? Dahl can put one in a glass box, drop the temperature to subzero and monitor how well it works.

Another piece of equipment can be used to simulate tropical humidity. And he can also perform a series of tests to check how they handle vibrations, stress and generally hold up in a range of conditions.

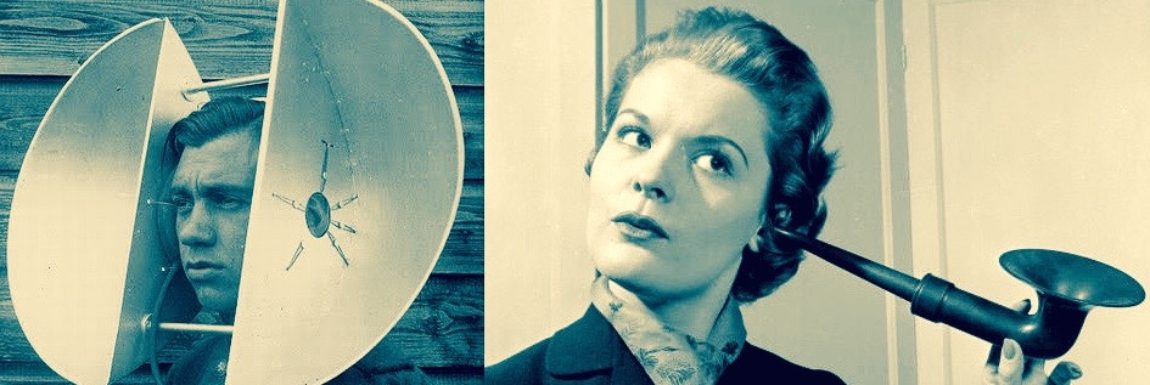

The very first hearing aid was invented in the 17th Century. It was called an ear trumpet. As the name suggests, it was basically a large cumbersome cone-shaped device that you stuck in your ear.

The remarkable evolution of hearing aids means that today you can enjoy a conversation around the dinner table without worrying about knocking over a glass with your ear trumpet. In fact, no one will likely know you are wearing hearing aids. And, more importantly, you might forget you are too.

Good post! I am envious, looks like a great tour